Besides project targets, also specific industry targets were identified, which take into account the different cell configurations (electrolyte and fuel electrode supported), the following standard operating conditions (such as temperature), and the application sectors of the participating companies. These can vary from the project targets and also from one industry to the other. The targets were provided in Deliverable D5.1:”Definition of the industrial targets”.

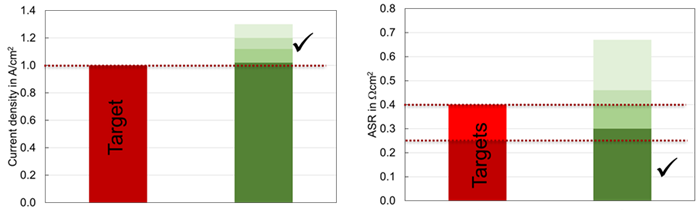

In the first part of the project, the focus was on the performance parameters maximum current density and area specific resistance (ASR). Several versions of improved electrodes / cells were developed. Some of them exceed the targets already, i.e. show higher achievable current density or lower ASR than required. This is illustrated in the figures below, where at least four cell versions developed in NewSOC (green columns) are compared to the targets (red columns). The assessment shows the advancement, even though not all details of the underlying conditions are included in the figure. After discussion with the industry partners, integration of the improved electrodes/layers into commercial cells & stacks have been agreed upon and are already in progress. The table shows the status of which specific integrations are planned at the time of mid-term and which improvements are of general interest and integration at a later stage or in the future.

Current density reached @1.3 … 1.5 V, temperature region from 650 … 900 oC, including electrolyte supported and fuel electrode supported cell configuration.

Figure 1. Industrial targets: current density and area specific resistance.

Table 1. Mapping of industry interest in the research topics at mid term of the NewSOC. x: Planned integration, (x) Potential integration.

|

Research \ Industry

|

ASC

|

ESC

|

MSC

|

|

I. Ni based fuel electrode

|

x

|

(x)

|

|

|

II. LSCF based oxygen electrode

|

x

|

(x)

|

|

|

III. Bi-metallic or tri-metallic Ni based fuel electrode

|

x

|

x

|

(x)

|

|

IV. Infiltrated, doped titanate backbone fuel electrode

|

|

x

|

(x)

|

|

V. Doped lanthanum chromite based fuel electrode

|

(x)

|

(x)

|

|

|

VI. Patterned electrode/electrolyte interface for Co-free oxygen electrode

|

x

|

(x)

|

(x)

|

|

VII. Honeycomb supported oxygen electrode

|

x

|

(x)

|

|

|

VIII. 3D printing of SOC

|

(x)

|

|

|

|

IX. Protective coating through inkjet printing

|

x

|

x

|

|

|

X. Ceramic coatings with innovative interface concepts

|

|

(x)

|

|

|

XI. Thin film atomic layer deposition barrier layers

|

x

|

(x)

|

|

|

XII. Thin film room temperature sputtering barrier layer

|

x

|

|

|